The aerospace market requires components that balance energy, excess weight, and overall performance underneath Excessive conditions. Rifeng PMI Foam, crafted by among the list of major PMI foam makers, provides a chopping-edge Answer customized for these tough necessities. Its exceptional Houses make it a crucial material in the construction of plane, helicopters, together with other Superior aerospace components. This site explores the special great things about Rifeng PMI Foam and its applications in aerospace engineering.

Table of contents:

maximizing Aircraft Structural Integrity with Rifeng PMI Foam

light-weight methods: decreasing pounds with no Compromising Strength

Thermal security of Rifeng PMI Foam in large-Temperature Environments

circumstance scientific tests: prosperous Integration of Rifeng PMI Foam in Aerospace

Enhancing Aircraft Structural Integrity with Rifeng PMI Foam

Structural integrity is really a cornerstone of aerospace layout, and Rifeng PMI Foam sets a completely new normal In this particular crucial spot. With its Extraordinary energy-to-excess weight ratio, it provides The best Basis for developing strong composite buildings although keeping longevity under large strain and demanding disorders. This Sophisticated foam not merely enhances stiffness and impression resistance but also minimizes weight, which can be essential for acquiring optimal effectiveness in aerospace programs. Its flexibility makes it a great option for structural panels, plane radomes, together with other essential elements where energy and dependability are non-negotiable. Engineers rely upon its mechanical click here toughness to ensure basic safety and functionality, even in superior-stakes, superior-functionality environments for example helicopter blades, unmanned aerial autos (UAVs), and other chopping-edge aerospace systems. Rifeng PMI Foam is often a reliable Option for pushing aviation and aerospace innovation to new heights.

light-weight remedies: minimizing bodyweight without the need of Compromising power

decreasing excess weight is significant in aerospace to reinforce gas performance, overall general performance, and sustainability. Rifeng PMI Foam is particularly engineered which has a fine mobile construction that minimizes resin absorption for the duration of core shaping, causing drastically lighter last parts. This Innovative style don't just minimizes substance fat and also cuts down on resin usage, even more contributing to your efficiency of generation procedures. The exceptional features of this foam cause decreased operational expenses, lessened environmental impression, and enhanced Electricity efficiency, rendering it a great Resolution to the aerospace field. Irrespective of its lightweight character, Rifeng PMI Foam does not compromise within the mechanical Houses of the material, making certain durability and trustworthiness in demanding applications. By providing an optimum stability of functionality and negligible bodyweight, Rifeng PMI Foam is now a trustworthy choice for brands in search of innovative, cost-efficient, and sustainable answers for modern aerospace issues.

Thermal Stability of Rifeng PMI Foam in superior-Temperature Environments

Aerospace components are made to face up to Serious environmental problems, together with intense mechanical worry and higher temperatures. Rifeng PMI Foam stands out with its Excellent thermal resistance, protecting security and responsible general performance even when exposed to curing temperatures of as much as one hundred eighty°C following correct procedure. This Sophisticated capacity ensures its success in demanding production procedures like vacuum infusion (VARI) and resin transfer molding (RTM), exactly where thermal endurance is important. Its outstanding thermal steadiness and longevity supply engineers with The arrogance to utilize it in warmth-crucial and higher-effectiveness applications, together with radome plane, aerospace interiors, and Superior structural composites. Rifeng PMI Foam don't just enhances materials general performance and also contributes to the longevity and basic safety of aerospace components under difficult problems.

scenario scientific studies: effective Integration of Rifeng PMI Foam in Aerospace

Rifeng PMI Foam’s innovative capabilities are already efficiently implemented in various aerospace tasks, showcasing its flexibility and benefit in substantial-efficiency applications. For illustration, its lightweight still potent Houses have revolutionized helicopter blade production, considerably reducing Total rotor body weight when maximizing durability and operational effectiveness. This don't just improves flight performance but in addition assists decrease gas use and servicing requirements eventually. likewise, UAV (Unmanned Aerial car or truck) designers have greatly benefited with the foam’s reduced resin absorption, which makes the production approach far more efficient, and its remarkable mechanical energy, which enhances flight effectiveness and In general structural integrity, even below demanding situations. Also, the fabric has established indispensable within the creation of radomes, in which its stiffness and Fantastic bonding Homes guarantee trustworthy general performance, even in Serious environmental disorders like high winds, temperature fluctuations, and moisture. These traits make Rifeng PMI Foam a vital ingredient in advancing cutting-edge aerospace technological innovation.

In conclusion, the flexibility and overall performance of the State-of-the-art foam material have manufactured it an indispensable asset throughout various aerospace purposes. Its exceptional combination of power, lightweight layout, and toughness proceeds to push the boundaries of innovation, enabling engineers to fulfill the demanding challenges of recent aviation and outside of. With its confirmed background, this materials is ready to remain a significant part in long run developments within the aerospace business.

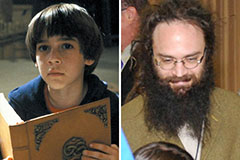

Barret Oliver Then & Now!

Barret Oliver Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!